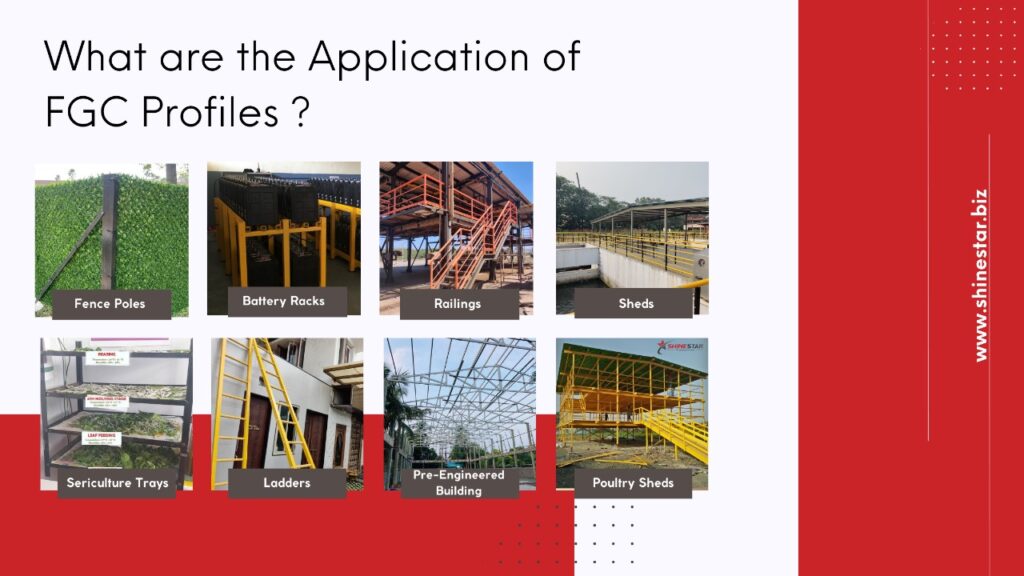

FGC Profile have become a popular choice in various industries due to their high strength-to-weight ratio, corrosion resistance, and durability. These profiles are used in a wide range of applications, from construction and infrastructure to marine and industrial environments. One common question that arises is whether all kinds of paints can be applied to FGC Profile. The answer is nuanced and depends on several factors, including the type of material, the surface preparation, and the specific paint being used.

Understanding FGC Profile

FGC profiles are made by pulling continuous fibers, glass fibers, through a resin matrix, which is then cured to form a solid composite material. The resulting profiles are lightweight, strong, and resistant to environmental factors like corrosion and UV radiation. However, the surface characteristics of FRP can pose challenges for paint adhesion.

Types of Paints Suitable for FGC Profile

-

Epoxy Paints

Epoxy paints are often recommended for FGC Profile due to their excellent adhesion properties and durability. They form a hard, protective coating that is resistant to chemicals, abrasion, and moisture. Epoxy paints are commonly used in industrial and marine environments where robust protection is required.

- Polyurethane Paints

Polyurethane paints offer good flexibility, UV resistance, and durability, making them suitable for outdoor applications. They adhere well to FRP surfaces, providing a smooth and long-lasting finish. Polyurethane paints are often used in architectural and automotive applications where appearance and durability are important.

Surface Preparation

Proper surface preparation is critical to ensuring good paint adhesion on FGC Profile. The following steps are generally recommended:

- Cleaning

The surface of the FRP profiles should be thoroughly cleaned to remove any dirt, grease, oil, or contaminants. This can be done using solvents or mild detergents followed by rinsing with clean water.

- Sanding

Light sanding of the FRP surface can help improve paint adhesion by creating a slightly roughened texture. This process removes any glossy finish and provides a better mechanical bond for the paint. It is important to use fine-grit sandpaper to avoid damaging the surface.

- Priming

Applying a suitable primer is essential for enhancing the adhesion of the topcoat. Primers designed for use with FRP materials can create a strong bond between the FRP surface and the paint. Epoxy-based primers are often recommended for their excellent adhesion properties.

Considerations for Different Paint Types

- Compatibility

Not all paints are compatible with FRP materials. It is essential to select paints that are specifically formulated or tested for use on composite surfaces. Manufacturers often provide guidelines or recommend specific products that work best with their FRP profiles.

- Environmental Exposure

The choice of paint should also consider the environmental conditions to which the FRP profiles will be exposed. Factors such as UV exposure, humidity, temperature fluctuations, and chemical exposure can affect the performance and longevity of the paint. Selecting paints with appropriate protective properties ensures the durability of the coating.

- Application Method

The method of paint application (brush, roller, or spray) can also influence the quality of the finish. Spraying often provides the most uniform and smooth finish but requires proper equipment and technique. Regardless of the method, applying multiple thin coats rather than one thick coat can improve adhesion and finish quality.

Conclusion

While not all kinds of paints can be applied to FGC Profile, using epoxy and polyurethane, they are suitable when used with proper surface preparation and priming. Understanding the specific requirements of the FGC material and the environmental conditions of the application is crucial for selecting the right paint and ensuring a durable, high-quality finish.

By following best practices for surface preparation and choosing compatible paints, you can effectively enhance the appearance and longevity of FGC Profile, making them even more versatile and valuable in various applications.